RELAUNCHING ROOTS SODA IN CANS

Saturday, 7 July 2018

I have not written to this blog for some time. And the only way to really explain my absence, is to tell our story. But first I need to skip the founding story of 2012, and start during the summer of 2013, where we had released Roots in bottles, and it had proved wildly more popular than I ever thought possible; we were inundated with positive feedback, sold out each week, and reached London in little over a month.

Despite our soda’s popularity, we couldn’t make enough of it to cover our monthly expenses. Cash starved, we used home-brew equipment to make our soda, but we needed commercial equipment to make it in large quantities, which when sold, would generate enough income to cover the company’s monthly running costs. Jon, an old friend, was interested in the project from the start. He persuaded family and friends to invest, and together we managed to raise half of the money we needed. There was not enough to buy the equipment we needed, but we went ahead; planning to demonstrate our business idea to raise the rest. But even now as we sold more soda than we could make, we couldn’t get the money we needed for commercial equipment from the banks or individual investors. Having never done anything this popular, I just wanted to make the company viable, so I changed the plan and decided to work day and night, seven days a week, to make soda round the clock. From our profits I reasoned, we would buy the equipment we needed. But even after hellish thirty six hour shifts, we still couldn’t make enough soda to cover our expenses. And the project would not have gone any further had it not been for my Stepfather, mum, and mother-in-law, who, impressed with what we achieved, offered to lend me the money we needed.

The sun shone overhead, while we unloaded the new equipment from the flatbed truck, parked outside Roots HQ. Fully installed, by the spring of 2014, the new equipment sailed through its trials. But after we produced thousands of pounds worth of soda, the bottling machine stopped working, and the manufacturer, who was based in Italy, evaded our requests for an engineer to come and fix it. Because our soda was made from natural fruit juices, which separate out when left to sit too long, it had to be dumped, after weeks of failed wrangling with the manufacturer. The situation became desperate; we had lost a lot of money, and we would soon go out of business, if the bottling machine could not be made to work, and so I decided to fix it myself. Unfortunately, I couldn’t do that whilst making soda for our customers on our old home-brew equipment, which was just too time consuming.

As we approached the close of 2014, the bottling machine was made to work, but there was always something to replace or repair. Furthermore, our funds were now terrifyingly low, and due to a tetchy bottling machine, I was struggling to both make and sell soda. With family and friend’s money at stake, I wanted to be sure I’d tried everything I could to make the company work, so I sold some of my shares, and finally persuaded the bank to give us a small loan. With the closing of 2014, I decided to hire a sales person. Since the beginning, sales had come easy to us, and I reasoned that we would be okay, if I could concentrate fully on production.

During the summer of 2015, we missed every single sales target, which was unnerving, because our sales had been strong, and that was the main reason why we accepted family and friend’s money. Aside from what we knew, which was that we had let our customers down previously, we tried to understand what had gone wrong. We had largely missed our sales targets because our soda was just too expensive, and if we continued to follow our original plan to reduce our price, we would go out of business before then. Because the plan required that we first sell a great deal of soda, to buy bulk ingredients at a discount. This seemed plausible in 2013, when we sold out every week, but in 2015, we quickly learnt that this was not going to work. So we weighed up our options, while reaffirming that we wouldn’t tamper with the quality of our ingredients. And so we considered and decided to repackage in cans, which would lower our packaging costs and ease our cash-flow, and we considered and decided to try and develop more affordable sodas. But we did not have the manpower to: run the company; raise more money for canning equipment; and develop new sodas, so we decided to hire more staff too, which of course was risky, because our overheads would increase, but doing nothing was riskiest of all.

As 2016 began, with the increased manpower, we quickly hit our first target: to develop low cost, low sugar sodas. And by the summertime, we’d begun to reverse the sales decline. Yet, as our situation improved that summer, we did not have the financial resources to capitalise on it, nor could we pursue our plans to release our soda in cans. We had used up a great deal of our funds turning things around. But it was more complicated than that. During this period my Stepfather was diagnosed with a terminal illness and passed away. Although he and my mum wouldn’t have been able to help us with all the funds we now needed, they had helped with small loans whenever funds were squeezed. Without that, production of our soda had grown erratic. Therefore, I had to face up to the fact that if I wanted to have any chance of getting the company through this, we were going to have to let everyone down all over again. And so I began to choke off production almost completely, to focus instead on fundraising, and to save whatever cash we had left, to keep the company alive for as long as possible, while we searched for a financial backer.

As I scrambled to save the company in 2016, I opened up every possible avenue to find funding, with the exception of crowd funding, which I immediately discounted having never been profitable. I attended workshops hosted by Scottish Enterprise, which ultimately led to a pitch for investment in a Dragon’s Den style competition. Having won, we were offered the funds we needed. But the deal meant that the shareholders would no longer have a say in the running of the company, which I only mention, because there will be those people who will ask. And I also mention that I’d got to know and like a number of the Angels, and that there was nothing different about this offer, in as far as I understand Angel Investment terms, but we felt that the deal did not take into consideration the amount of money that we had collectively invested in the company; simply put, we felt it unfair. Despite this, and under considerable financial pressure at home, the shareholders let me make the final decision; they did not want to accept the offer despite the alternative of almost certainly going out of business, but they were prepared to support whatever decision I made. And so I decided not to accept the offer.

It was the beginning of 2017, in wintertime, when we turned down the investment offer. There was little money, and little appetite left within our group to fund the enterprise further. Furthermore, were we to look for another backer, and were we successful, it was likely to be a similar offer. And it was around this time that Hannah departed, following Shaun who had left the previous summer. Their departure was understandable, for the company had stood still, and struggled to find the funds it needed.

But the experience had hardened a small group of shareholders, and with them I discussed the beginnings of an alternative plan: what if we could get it to work at a smaller scale? What if we didn’t tie-up as much cash in raw materials? And what if we didn’t need as many people? It meant to turn a profit, our monthly sales target would reduce by three quarters. I was talking about automation, and changing our packaging to cans again.

There was little money left to survive much longer, never mind an automated canning line. But there was hand operated canning equipment at a lower cost, and there was the will to purchase it within this hardened group. Of course, I would have to automate it myself, which I reasoned I could do, having taught myself how to build a car as a teenager, but after the equipment, and money for working capital, there was only a few hundred pounds left to automate the canning line with. Not enough, but enough if I designed and built the electronic components myself. Enough if I took that fucking bottling machine apart, and used its electrical and pneumatic components to power the canning line. I could also get a cheap microprocessor and write the software to control it all.

Deep in the heart of summertime, the transition to cans had ballooned. Chiefly, we decided that we should rebrand before we relaunched. But like the automation, there was no money for it, and so this project had fallen upon me. Without much in the way of experience, I took online courses in graphic design, and alongside the automation project, began the rebrand, which was like a Russian doll that opened up a need for a new website, and marketing materials. But the hardened group of shareholders were doing all they could to help. I sent my designs to Chris, who had done the early branding work, for feedback, and as he did in 2012, Jon worked tirelessly to find the investment we desperately needed for working capital.

The requirement to learn so many new skillsets at once was overwhelming, while the launch date for the cans slipped from the summer to Christmas, to New Year 2018, to the spring, and then back to the summer again. And suppliers slipped deadlines too. But the biggest battle was with myself, because I failed so often, I failed multiple times every single day, and I admit that there were times where I just wanted to quit, but I wanted more to finish what I had started.

And when the money was running out again, I wrote to the shareholders again. And the group grew more determined to see this through. Moreover, the shareholders helped in every way they could, raising money, offering advice, lending support, and helping out with the first canning runs. And when it looked as though the canning line was finally finished, there was still more learning, resulting in tweaks and changes, to make sure that before we relaunched, everything would work right this time.

And so today, having finally finished our transition from bottles to cans, this part of our story ends, and a new one begins.

Mark

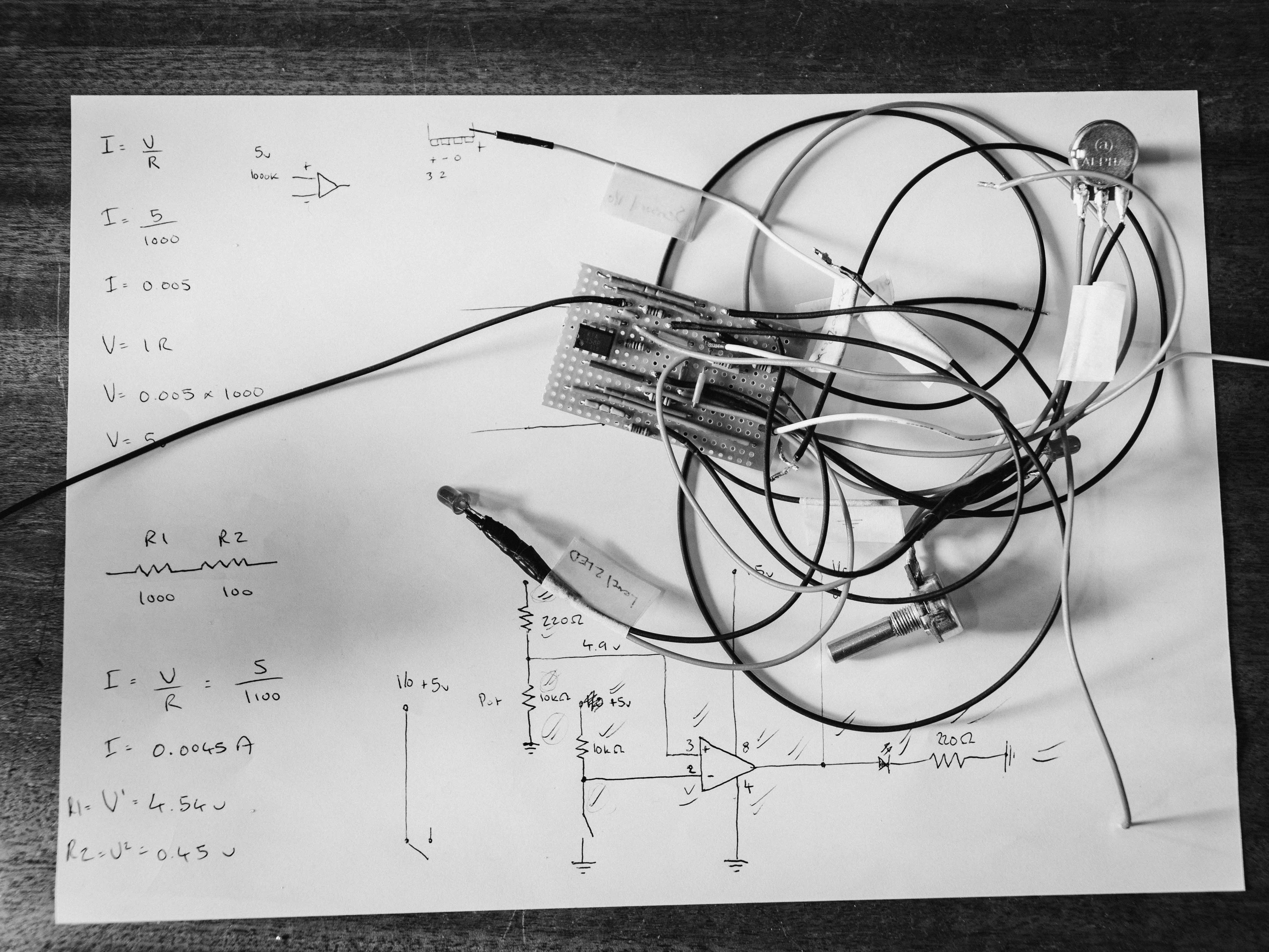

Soldering liquid level sensing circuit.

Finished liquid level sensing circuit.

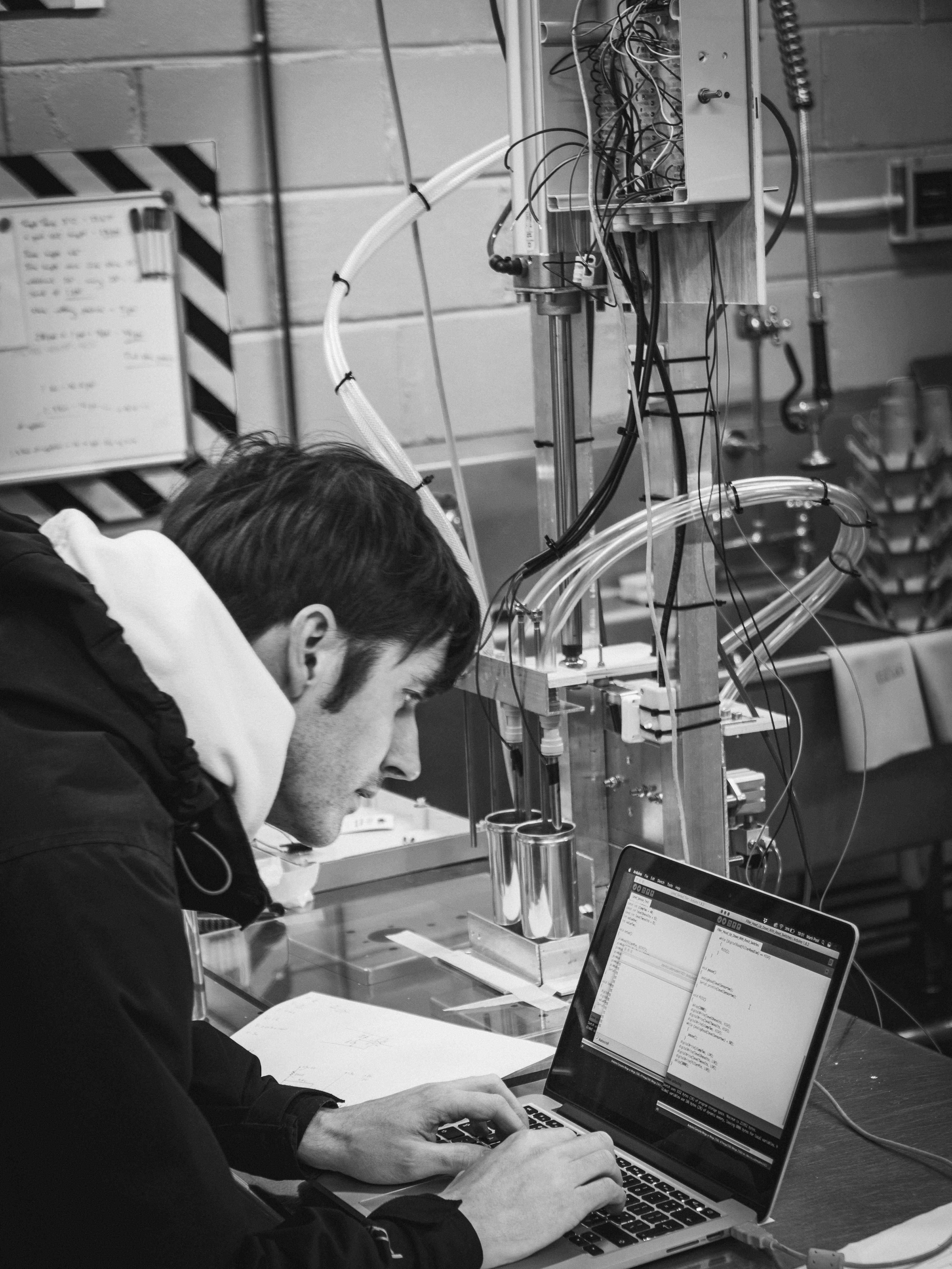

Early tests of code, pnematics, and level sensing. Some components are taped together for the tests.

Wiring up relays.

Watching the can seamer run for the first time.

Contact

e: hello@rootssoda.co.uk

t: +44 (0)131 552 4495

Unit 13

New Broompark

Edinburgh

EH5 1RS

© 2018 Roots Soda Ltd.